DEVELOPMENT OF HAZARD ANALYSIS CRITICAL CONTROL POINTS (HACCP) PROGRAM IN THE PRODUCTION OF A TRADITIONAL NIGERIA FOOD- UGBA

Abstract: The Hazard Analysis Critical Control Points (HACCP) program aims at ensuring the safety of food products. Such a program has been developed for the production of a Traditional Nigerian Food known as Ugba which is gotten from African oil bean seeds. The hazards, critical control points, and corrective actions have been summarized in comprehensive tables. The physical hazards such as stones, sands and metallic objects were mixed in with the seeds from the farm level; contamination from the water used in washing was also identified. The temperature change from 28oC to 33oC and back to 29oC were determined. Total coliform count, total bacteria count and total fungal count and other pathogens were detected during processing and post-processing of ugba and this indicates that the processing of ugba using the traditional method is subject to microbial contamination. The phytochemicals – saponin, oxalate, and phytate were determined, and phytate content was higher (71%) due to the addition of salt before fermentation. Training of processors about Hazard Analysis Critical Control Points (HACCP), environmental sanitation personal hygiene and use of good equipment were also suggested as strategies to improve the safety of this traditional Nigerian food.

CHAPTER ONE

INTRODUCTION

- BACKGROUND OF INFORMATION

The Hazard Analysis Critical Control Point (HACCP) system is designed to identify, prioritize and control potential problems. It has become synonymous with food safety. It is a worldwide recognized systematic and preventive approach that addresses biological, chemical and physical hazards through anticipation and prevention rather than through end-production inspection and testing (Barbut and Pronk, 2014).

The Hazard Analysis Critical Control Point program was developed in the early 1970s at the Pillsbury Food Company while developing food for the National Aeronautic and space administration program and the US Army Research laboratory (Yiannas, 2009). Generally, it was developed to replace the Randam Finished Product Quality Control Program, which could not guarantee the level of safety required for the space programme. Implementing a HACCP program usually starts with putting together a team of people from different areas, who will review the entire production of a particular product or product(s) as the case may be (Yiannas, 2009).

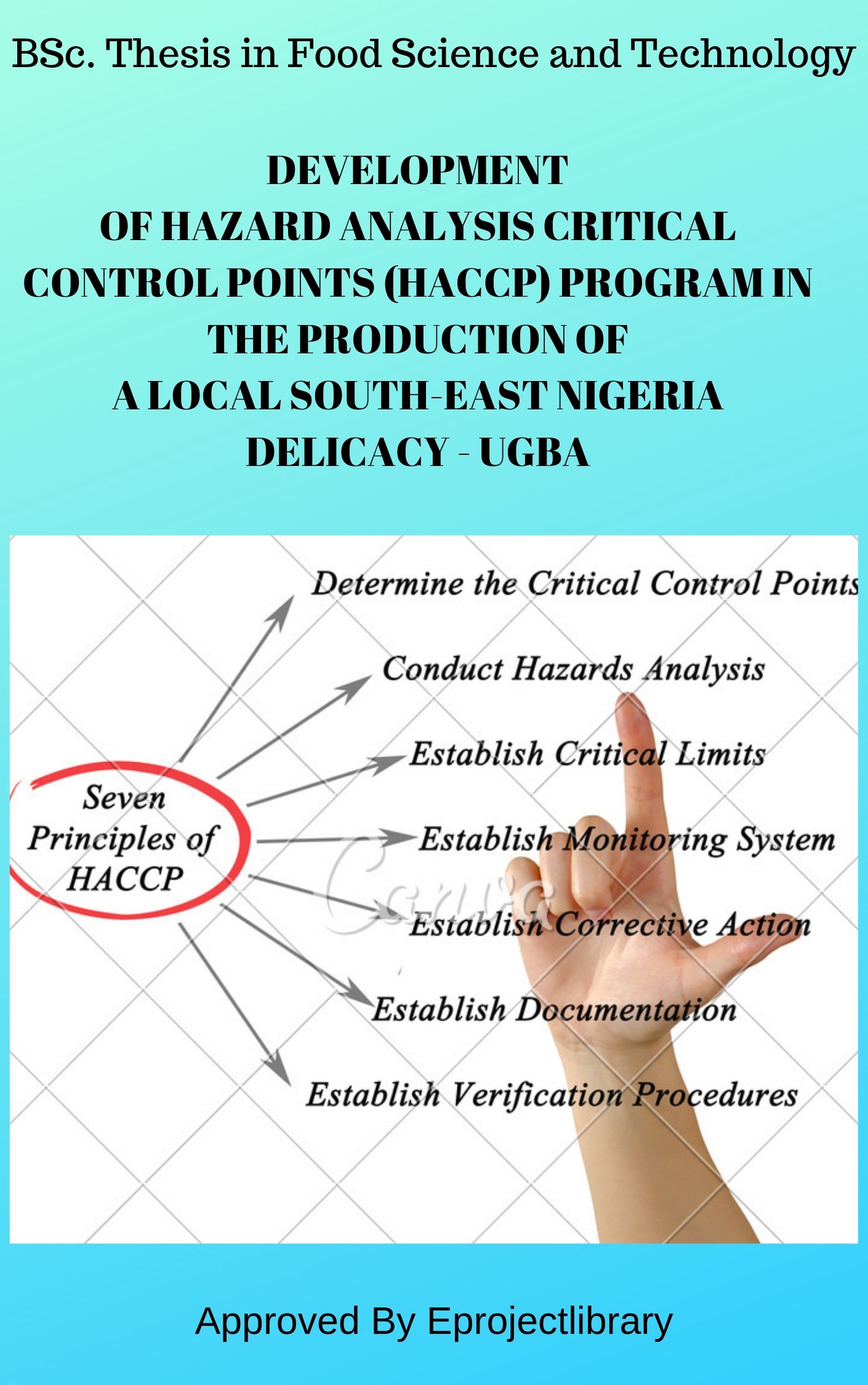

The seven principles of HACCP:

- Principle 1: Conduct a Hazard Analysis

- Principle 2: Determine the critical control points (CCPs)

- Principle 3: Establish critical limits

- Principle 4: Establish monitoring procedures of the Critical control points (CCP)

- Principle 5: Establish corrective Actions

- Principle 6: Establish verification procedures to confirm that the HACCP system is working.

- Principle 7: Establish record-keeping and documentation procedures (Sondrou, 2009).

The 12 Steps in Implementing HACCP principles

- Assemble HACCP team

- Describe the product

- Identify intended use

- Construct flow diagram

- On-site confirmation of flow diagram

- Conduct a hazard analysis, list all potential hazards associated with each step and consider any measures to control identified hazards.

- Determine critical control points

- Establish critical limits

- Establish monitoring procedures for each critical control points

- Establish verification procedures

- Establish record-keeping and documentation (Pronk, 2014).

These principles of HACCP are applied in so many food products as well as traditional Nigerian food delicacies (or local delicacies). Traditional Nigerian food (or local delicacies) refer to foods and dishes that are passed through generations, and are traditional in nature and may have a historic precedent in a regional cuisine or local cuisine (Guerrero et al., 2010).

Most of these traditional Nigerian food, for example, ugba (African oil bean), are made locally by individuals in their homes under highly variable conditions and where the application of HACCP system is not considered and employed. This might therefore give rise to certain hazards (Physical, biological or chemical) which might cause harm to the consumer(s) if control measures are not taken (Iwuoha and Eke, 2006). Ugba, a product of alkaline fermentation of African oil bean seeds (Pentaclethra macrophylla) is very popular among the Ibos and other ethnic groups in southern Nigeria. The product serves both as a delicacy and a food flavouring agent (Adewunmi, et al., 2014). As an important nutritional item, ugba is very rich in protein. It similarly plays an economic, social and cultural role among the Ibos in the eastern part of Nigeria. The production of ugba is usually pursued as a family business that has become an art that is handed over from one generation to another (Brown, et al., 2009).

African oil bean seed also known by its scientific name, Pentaclethra Macrophylla is a native to the tropical regions of Africa and has been cultivated since 1937. The crops belongs to the legumunosae family and the Mimoseideae sub-family (Agbogidi and Ayelo, 2010). The African oil bean seed is an excellent source of energy, protein, amino acids, phosphorous, magnesium, iron, vitamins, calcium, manganese and copper. It is also an excellent source of phytonutrients such as tannins, alkaloids, sterols, flavonoids, glycosides and saponins, though most of the minerals and vitamins (e.g. phosphorus) are eradicated during fermentation process.

1.2 RELATED WORKS

In an article published in 2010 by Oguntoyinbo, F.A. tilled Development of Hazard Analysis Critical Control Points (HACCP) and Enhancement of Microbial Safety Quality during production of fermented legume based Condiments in Nigeria”. It was concluded that training of food processors about HACCP, processing, environmental sanitation and personnal hygiene are strategies to improve the safety of these traditional fermented condiments hereby preventing food safety hazards (like physical hazards eg metallic objects, stones, chemical hazards and also biological hazard).

In another article written and published by Danbaba Nahemiah, Oyeleke Solomon, Kolo Isa Nmausman, Hauwa Isa Fati and Mayi Alhassan Tawaka in 2014, showing the “Application of Hazard Analysis and Critical Control Point (HACCP) in the production of soy-kunun-zaki” was concluded that Nigeria lacks proper information on food safety and its importance. Kunun-zaki been a popular drink in the northern part of Nigeria has been made traditionally without patting some important factors to practice. The article furthermore elaborated more on how this local cereal-based beverage can be produced without any fear of food safety hazards by the application of Hazard Analysis Critical Control Point (HACCP), as well as carrying out chemical and microbiological analysis which will increase consumers confidence.

1.3 PROBLEM STATEMENT

There are lots of problems faced during the production of ugba as well as its preparation into various traditional Nigerian food. The presence of hazards (physical, chemical and biological) are the major problems encountered.

In our homes, during production and preparation, certain factors are disregarded due to ignorance and some of these traditional Nigerian food delicacies are produced and prepared in an unhygienic environment, using certain rudimentary equipments without consideration for General Manufacturing Practice (GMP) which might be the cause of both physical and microbiological hazards.

1.4 AIM/OBJECTIVES

The main objective of this work is to develop a hazard analysis critical control point (HACCP) programme for ugba production from African oil bean seeds. This will be achieved with the following specific objectives;

- African oil bean seeds will be cooked and fermented traditionally.

- The sliced fermented ugba will be used in the preparation of some traditional Nigerian Food.

- Sensory evaluation of the delicacies will be analyzed in other to determine the consumers acceptability, and

- The Hazard and critical control points will be identified and the corrective measures highlighted.

1.5 SCOPE OF WORK

This work covers the collection of materials, production of ugba from African oil bean seeds, preparation of some traditional Nigerian food delicacies, sensory properties and developing a hazard analysis critical control point (HACCP) programme of the production and preparation of ugba.

OTHER TRADITIONAL FERMENTED FOODS IN NIGERIA

ikenna –

Exactly what I was looking for